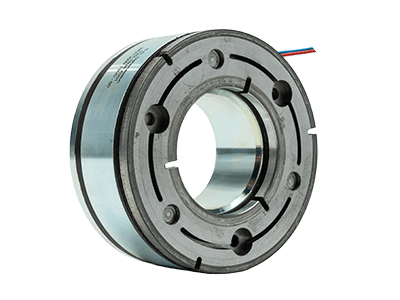

Flange mounted power on brake

Backlash free, electromagnetic flange mounted power on brake for energised stopping in static and dynamic applications.

Enquire NowKey features

- Backlash free

- Long life expectancy

- Durable construction

- Low maintenance

- Optional voltage

- Choice of drive hubs to suit application

- Customisable

Product description

The flange mounted power on brake, also known as a single-surface or single-disc brake, generates a braking effect when the coil is energised. The brake body is mounted on the drive and when energised (working current) with nominal voltage, the armature disc is attracted through the minimal air gap to generate a static braking effect.

This power on brake is typically used to safely stop and hold a rotating force in position. Due to the integrated, abrasion-resistant and asbestos-free brake lining, it can also be used for dynamic braking applications. The force can be regulated up to the nominal voltage by an external voltage regulator.

Flange mounted power on brakes are suited to automation within machinery, material handling and warehouse logistics as well as military, security and medical applications.

Zero backlash

The durable construction means that this power-on brake is essentially zero backlash (torsionally rigid) creating an increased level of safety and accuracy.

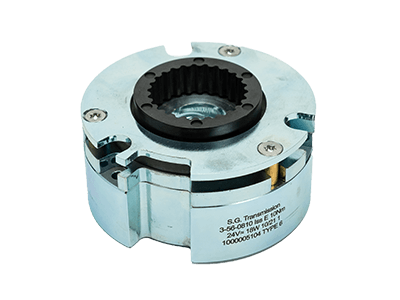

Multi-pole

Our electromagnetic power on brake also comes in a range of high torque (multi-pole) versions, which give a higher static torque. These are generally used for static holding applications, but may be used for limited occasional dynamic use, as they generally do not have an embedded friction ring in the working face.

The segmentation of the pole face offers an optimisation of the iron-copper ratio, increasing the proportion of iron in the holding surface and the usable iron surface. This technology can also be applied to clutches and power on brakes.

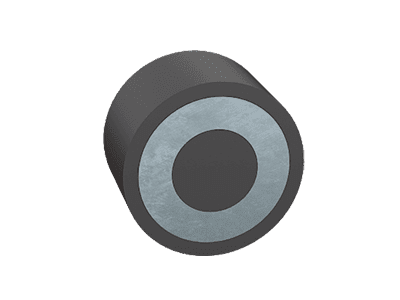

Armature and fixing options

Depending on design layout, various armature styles can be supplied (C.L, C.C or C.R). These consist of an armature plate and return spring, in C.L. form, or an integral hub with a bore and key way according to DIN 6885 in C.C. or C.R. formats.

Customisation

As experts in customised electromagnetic clutches and brakes, SG Transmission can work with you to adapt an existing design or develop a bespoke solution. The information found within our datasheets are provided as a general guide for size and force data. For customer or application specific requests, get in touch with our expert engineering team.

Our products are manufactured and tested to DIN VDE 0580 and are available with ISO Class F/H insulation (155°c) as standard or higher on request.

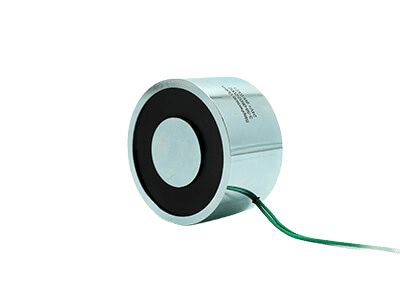

For electromagnetic power-off brakes, see our fail safe permanent magnet power off brake or our spring applied brake.

Key features

- Backlash free

- Long life expectancy

- Durable construction

- Low maintenance

- Optional voltage

- Choice of drive hubs to suit application

- Customisable

Product description

The flange mounted power on brake, also known as a single-surface or single-disc brake, generates a braking effect when the coil is energised. The brake body is mounted on the drive and when energised (working current) with nominal voltage, the armature disc is attracted through the minimal air gap to generate a static braking effect.

This power on brake is typically used to safely stop and hold a rotating force in position. Due to the integrated, abrasion-resistant and asbestos-free brake lining, it can also be used for dynamic braking applications. The force can be regulated up to the nominal voltage by an external voltage regulator.

Flange mounted power on brakes are suited to automation within machinery, material handling and warehouse logistics as well as military, security and medical applications.

Zero backlash

The durable construction means that this power-on brake is essentially zero backlash (torsionally rigid) creating an increased level of safety and accuracy.

Multi-pole

Our electromagnetic power on brake also comes in a range of high torque (multi-pole) versions, which give a higher static torque. These are generally used for static holding applications, but may be used for limited occasional dynamic use, as they generally do not have an embedded friction ring in the working face.

The segmentation of the pole face offers an optimisation of the iron-copper ratio, increasing the proportion of iron in the holding surface and the usable iron surface. This technology can also be applied to clutches and power on brakes.

Armature and fixing options

Depending on design layout, various armature styles can be supplied (C.L, C.C or C.R). These consist of an armature plate and return spring, in C.L. form, or an integral hub with a bore and key way according to DIN 6885 in C.C. or C.R. formats.

Customisation

As experts in customised electromagnetic clutches and brakes, SG Transmission can work with you to adapt an existing design or develop a bespoke solution. The information found within our datasheets are provided as a general guide for size and force data. For customer or application specific requests, get in touch with our expert engineering team.

Our products are manufactured and tested to DIN VDE 0580 and are available with ISO Class F/H insulation (155°c) as standard or higher on request.

For electromagnetic power-off brakes, see our fail safe permanent magnet power off brake or our spring applied brake.

To download the technical drawings for this product fill in your details below and we will send you a link to the files.

"*" indicates required fields

Flange mounted power on brake technical drawing

See related downloads for full datasheet

Download drawingsSee related downloads for full datasheet

| Size | Torque TS (Nm) | Max P20 (W) | A1 H9 | A2 | B | C4 | Max E2 H7 | H8 | E5 | G | H2 | K | N1 | N2 | R2 | S1 | T | U1 x4 | U2 | U7 | V | W1 | W4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 00 | 0.30 | 5 | 38 | 28.6 | 17 | 7 | 6.5 | 11 | 10 | 0.1 | - | 5 | 33.3 | 19.5 | 14 | 9.7 | 1.5 | 3.2 | 2x2.6 | M3 | 1 | 4.5 | 4.7 |

| 01 | 0.60 | 6 | 38 | 30 | 18.5 | 10 | 6.5 | 11.5 | 12 | 0.1 | - | 5 | 33.3 | 19.5 | 16 | 12.8 | 1.5 | 2.6 | 2x2.6 | M3 | 1 | 8 | - |

| 02 | 0.75 | 6 | 45 | 32 | 19.5 | 10 | 6.5 | 13 | 12 | 0.1 | 3 | 5 | 38 | 23 | 17 | 12.8 | 2 | 3.5 | 3x2.6 | M3 | 1.5 | 8 | 4.8 |

| 03 | 1.20 | 8 | 54 | 40 | 23.2 | 12 | 10 | 19 | 17 | 0.15 | 3.2 | 6.1 | 47 | 30 | 20 | 15.3 | 1.5 | 3.5 | 3x3.1 | M3 | 1.5 | 9.5 | 5.8 |

| 04 | 1.60 | 8 | 62 | 42 | 23.2 | 12 | 10 | 19 | 17 | 0.15 | - | 6.1 | 54 | 29 | 20 | 15.3 | 2 | 5 | 2x3.1 | M3 | 1.5 | 9.5 | 5.8 |

| 05 | 3 | 10 | 65 | 50 | 25.2 | 12 | 15 | 26 | 24 | 0.2 | 3.2 | 6.1 | 58 | 38 | 22 | 15.3 | 2 | 3.5 | 3x3.1 | M4 | 1.5 | 9.5 | 6 |

| 06 | 8 | 12 | 80 | 63 | 22 | 15 | 17 | 35 | 27 | 0.2 | 3.5 | 6.1 | 72 | 46 | 18 | 19 | 2 | 4.5 | 3x3.1 | M5 | 1.5 | 11.5 | 7.5 |

| 07 | 8 | 12 | 89 | 66.5 | 36 | 15 | 17 | 27 | 27 | 0.2 | - | 6.1 | 79.5 | 46 | 32 | 19 | 2 | 5 | 3x3.1 | M5 | 1.5 | 11.5 | - |

| 08 | 16 | 18 | 100 | 80 | 24.5 | 20 | 20 | 42 | 32 | 0.2 | 4.3 | 8 | 90 | 60 | 20 | 24.7 | 2.5 | 5.3 | 3x4.1 | M5 | 2 | 16 | 8.7 |

| 10 | 32 | 25 | 125 | 100 | 28 | 25 | 30 | 52 | 42 | 0.2 | 5 | 9 | 112 | 76 | 22 | 30 | 3 | 6.5 | 3x5.1 | M6 | 2 | 19 | 11 |

| 11 | 32 | 25 | 143 | 105 | 44 | 25 | 30 | 47.6 | 42 | 0.2 | - | 9 | 127 | 76 | 38 | 30 | 3 | 7.5 | 3x5.1 | M6 | 2 | 19 | - |

| 12 | 65 | 32 | 150 | 125 | 31 | 30 | 35 | 62 | 49 | 0.3 | 5.5 | 10 | 137 | 95 | 24 | 37.2 | 3.5 | 6.5 | 3x6.1 | M6 | 2.5 | 24 | 13 |

| 13 | 65 | 32 | 165 | 125 | 39 | 30 | 35 | 52.4 | 49 | 0.3 | - | 10 | 149 | 95 | 33 | 37.2 | 3.5 | 10.2 | 3x6.1 | M6 | 2.5 | 24 | - |

| 16 | 12 | 45 | 190 | 160 | 35 | 38 | 40 | 80 | 65 | 0.3 | 6 | 13 | 175 | 120 | 26 | 48 | 4 | 9 | 3x8.2 | M8 | 9 | 30 | 16 |

| 20 | 240 | 45 | 230 | 200 | 41.6 | 48 | 60 | 100 | 92 | 0.5 | 7 | 136 | 215 | 158 | 30 | 59 | 5 | 9 | 3x10.1 | M8 | 11 | 39 | 20 |