Fail-safe electromagnetic brakes

Accurate and reliable braking when power is disengaged to guarantee safety

Fail-safe brakes automatically stop movement when power is removed and are beneficial in applications where quick and accurate braking or holding is required. When the power is re-engaged, the brake will release allowing the shaft to rotate or movement to continue.

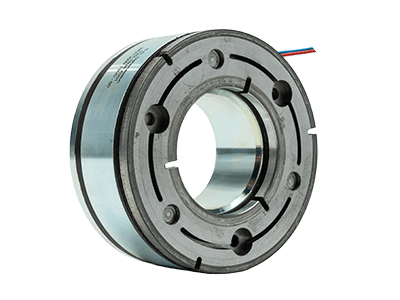

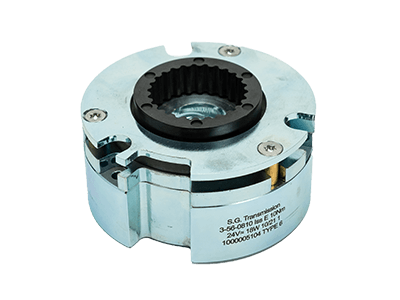

Fail-safe brakes generate torque through the clamping together of friction surfaces, the method of clamping determines the two available types as spring applied or permanent magnet brakes. It has been common place to apply spring applied brakes to static holding applications (rear of motors) and permanent magnet brakes to frequent on-off applications (rear of servo motors).

Spring applied brakes use multiple springs and a magnetic coil to clamp the rotor (with friction surfaces), when power is applied to the coil the magnetic force pulls an armature plate away from the friction surfaces. The springs in the coil are compressed and the rotor is free to rotate.

Permanent magnet brakes use a permanent magnet disc to generate magnetic energy which clamps the friction surfaces together against a stationary housing to give the required braking torque. When power is returned to the brake coil, the armature plate is released the shaft is free to rotate.SG Transmission is able to offer three types of fail-safe brakes namely, spring applied, permanent magnet and permanent magnet toothed brakes.

- Power off brake engagement

- Fail-safe

- Horizontal and vertical mounting

Contact an expert to discuss your backlash free solution

"*" indicates required fields

Our fail-safe brake solutions

Latest news

Read the latest company news, customer success stories and industry blogs from our leading experts on the topic of electromagnetics and the future of automation.